Welcome to Techsavvy Mechanicals LLP

Techsavvy Mechanicals LLP, an ASME U Stamp Certified company, stands at the forefront of engineering innovation, delivering specialized design and manufacturing solutions for process equipment across diverse sectors. Renowned for our expertise, we serve industries such as Chemicals, Petrochemicals, Vegetable Oil, Food, Pharmaceuticals, and Brewery with precision and dedication. Our commitment to quality is reflected in our adherence to ISO 9001:2015 standards from inception and our recent certifications, including ISO 3834-2 and HP0.

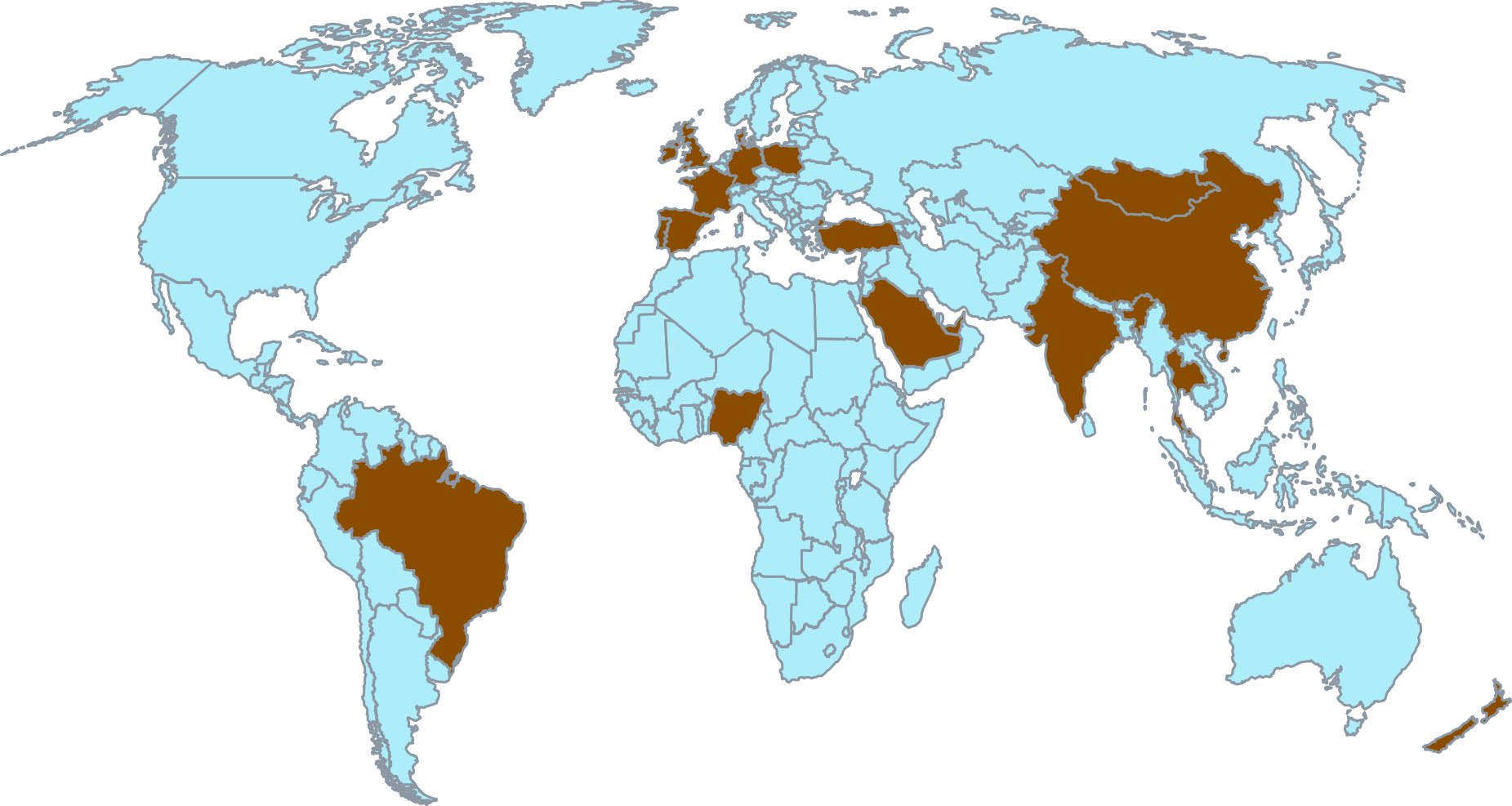

⦿ Humble Beginnings to Global Leadership From our modest start as a supplier of machining components, Techsavvy Mechanicals LLP has evolved into a globally recognized leader, offering a comprehensive suite of sustainable solutions for process equipment supply.

⦿ Specialized Expertise We are distinguished by our proficiency in working with special metals, manufacturing critical and high-pressure components, and producing unique, tailor-made equipment.

⦿ Industry-Relevant Experience Our leadership draws from extensive experience with industry giants like Alfa Laval, ISGEC, Sulzer, TEMA, and Extern, infusing our operations with deep industry knowledge and best practices.

⦿ Expanding Horizons As we continue to grow, we are scaling our operations to serve a broader spectrum of industries, applications, and products.

⦿ Competitive Edge Our vast experience in sectors such as Chemicals, Petrochemicals, Vegetable Oil, Food, Pharmaceuticals, and Brewery positions us uniquely in the market, setting us apart from our competitors.

Techsavvy Mechanicals LLP remains committed to driving innovation and delivering excellence in every project we undertake, ensuring our clients receive the highest quality products and services.